-40%

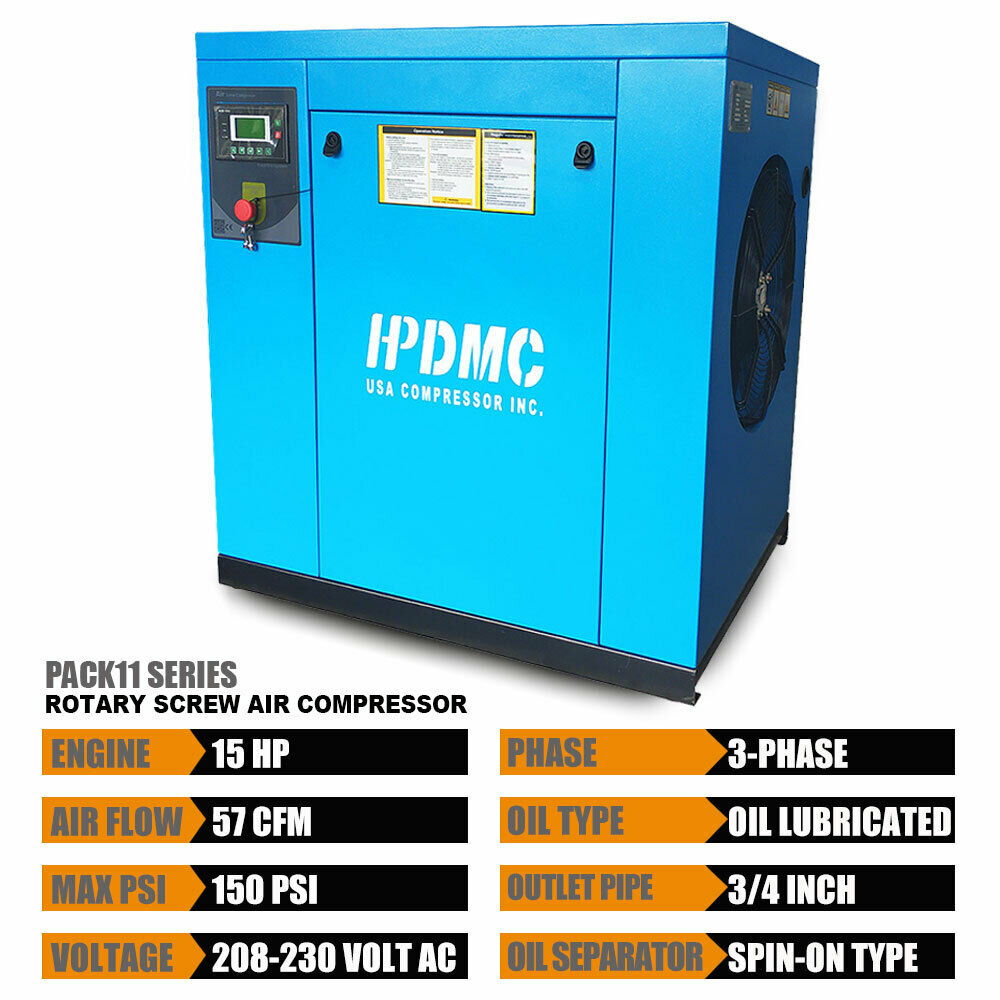

HPDMC Rotary Screw Compressor - 230 Volts, 3 Phase, 15 HP, 57 CFM, PACK11

$ 2272.51

- Description

- Size Guide

Description

HPDMC Rotary Screw Compressor - 230 Volts, 3-Phase, 15 HP, 57 CFM, Industrial Air Compressed System - PACK11(pictures shown may vary from actual product)

Specifications: 15hp / 11kw, 230 volts / 60hz / 35 amps, 3 Phases

Working pressure: 125 -150 psi / 8 - 10 bar, Air flow: 57 - 46 CFM

Approved: CE standard electrical motor + CE Listed PLC controls. Size: 45 Length x 40 Depth x 49 Height ( inch ), Weight: 900Ibs

Spin-on Air Oil Separator: Air cooled aftercooler to reduce discharge air temperatures with the spin-on oil filter and separator element, minimizes downtime.

Application: It can widely used for production, pharmaceutical, textile, auto repair, aviation, metallurgical and other industrial fields, can used safely in all applications of small and medium sized businesses.

About Us

HPDMC center has been engaged in the development and production of screw compression technology and high pressure breathing air system for more than ten years. Its products include variable frequency screw machines, industrial frequency screw machines, industrial frequency screw machines, permanent magnet variable frequency screw machines, permanent magnet variable frequency machines, Double-voltage industrial frequency screw machines have been widely used in various industries.

Our manufacture base occupies 279,760 square feet and owns over 150 employees, including technicians, after service representatives, and production associates. In 2019, our vision is to expand the factory area to 350,000 square feet and raise the number of employees to 200.

Why Choose HPDMC Rotary Screw Air Compressor for industries?

HPDMC Rotary Screw Air Compressors with quiet and compact design, can be install almost anywhere, can meet the compressed air demands of a tire shop maintenance shop,vehicle body shop,paint shop or automotive dealership.

Reduce energy costs

Reliability-High efficiency motor, up to 96%

Long-life V-belt or direct drive

High efficiency air intake filter and powerful motor

Standard silent enclosure is designed to reduce vibration and noise levels

Packing & Delivery - Professional packing and delivery services.

Reliable Quality - Hundreds of R & D and production team

4 service centers in USA

MD / 815 Central Ave. Ste. F-G Linthicum Heights, MD 21090

CA / 1001 N Todd Ave, Azusa CA 91702

IL / 5000 W. Roosevelt, Back of the building, dock 24-33,Chicago, IL 60644

TX / 1336 W Carrier Pkwy, Grand Prairie, TX 75050

Low Noise Level

Silent box design, using composite sound-absorbing material, low noise.

80 dBA operational noise level for a quite work enviroment

Energy saving

Motor efficiency is higher than asynchronous motor

No no-load power consumption

No over-voltage power consumption

Save energy during startup

Saves the waste of control pressure bandwidth and uses constant voltage output

Efficient

Two-stage compressor head is 17% more efficient than single-stage compression

With permanent magnet motor, the efficiency is 5-7% higher.

Reduce no-load consumption (savings average about 30%)

.

Eliminate unnecessary pressure and waste, save 7-8% efficiency

High reliability

The two-stage compression screw head reduces the compression ratio, reduces the load on the bearing, improves the life of the head, has good reliability, and is durable.

There are no leaks inside the machine. The air filter has a large filtering area and uniform air intake.